APS : SiC MOS shipments soar, with 5 major strategies to address "internal competition"

Looking back at 2023, what progress has been made in the silicon carbide and gallium nitride industry? What changes have occurred? What new opportunities and challenges will 2024 usher in ?

In order to better understand the industrial pattern and explore the direction of future advancement, news outlet Hang Jia Shuo and the Hangjia Aurora Award planned the special report "Expert Outlook - 2024, Full Speed Ahead".

The guest of this issue is Chau Wing Chon, CEO of APS. In the next few days, more leading enterprises will participate in the "Expert Outlook".

Shipments exceeded 24 million Expanded automotive OBC and optical storage applications

Hang Jia Shuo: What achievements did your company make in 2023?

Chau Wing Chon: In 2023, our company achieved good results in many aspects:

Firstly, the shipment volume of silicon carbide devices.

As of 2023, the cumulative shipment of 1200V silicon carbide devices has exceeded 24 million, receiving high praise from customers in the new energy vehicle, consumer electronics, and industrial markets. Among them, SiC MOSFET's revenue has rapidly increased. Compared to 2022, the revenue generated by SiC MOSFET has increased from 17% to 50%, indicating market recognition of our products, driving the continuous growth of the company's business and the improvement of its market position.

Next is the breakthrough in the application of new energy OBC in the market.

We have passed the customer's on-board verification and have supplied a large number of power supplies to leading companies in the automotive industry. In terms of 11KW OBC, APS 1200V silicon carbide MOSFET has also been validated by clients.

The third is to further increase the market share of photovoltaic storage and charging.

In 2023, through close cooperation with customers and focusing on their needs for optical storage inverters, we successfully developed and launched a new SiC diode that is more suitable for the current needs of optical storage users. It passed customer validation and achieved large-scale production.

Key Tasks for APS in 2023: New Products, Vehicle Regulations, Market, and Innovation

Hang Jia Shuo: What key tasks will your company focus on to achieve these results?

Chau Wing Chon: In 2023, our silicon carbide business will mainly focus on product development and market expansion.

Firstly is the launch of the third-generation silicon carbide MOSFET, which includes various mainstream market specifications, such as 1200V 14/18/30/40/80m Ω and 750V 11m Ω.

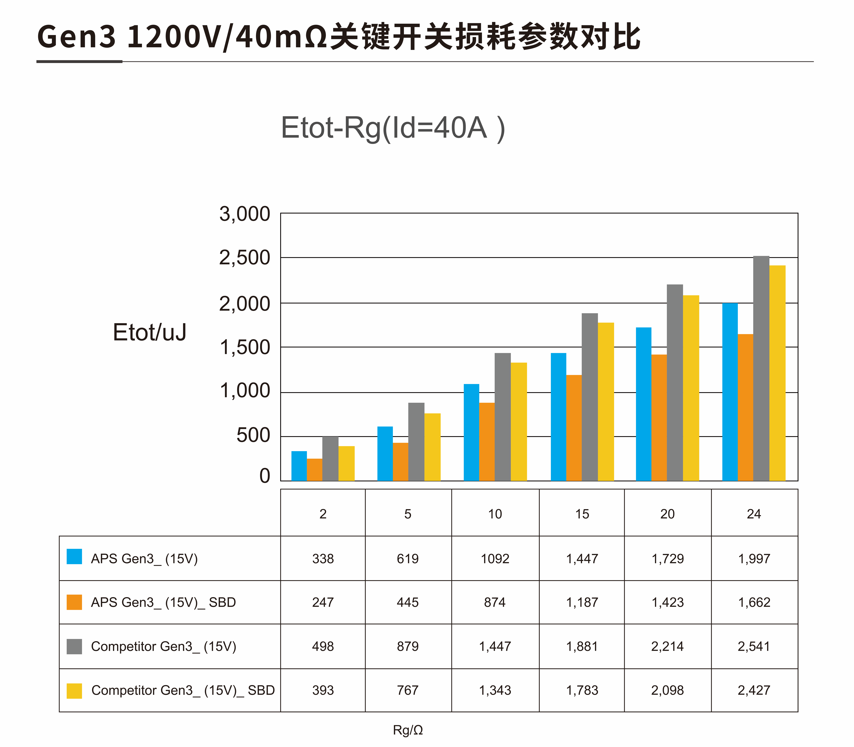

Compared with our products from previous generations, the new generation SiC MOSFET products have better parameter consistency, lower switching losses, and better conductivity characteristics which can meet the high reliability and performance requirements in fields such as charging piles, photovoltaic & energy storage, and on-board OBC/DCDC/main drive. Our third-generation silicon carbide MOSFET has significantly improved reverse recovery losses and total switching losses under different gate drive resistances.

Second is the breakthrough in automotive grade silicon carbide.

APS independently developed 1200V 35/70/160m Ω and 650V 30/45/60m Ω automotive grade SiC MOSFET devices have successfully obtained AEC-Q101 automotive grade reliability certification and passed HV-H3TRB testing, making APS one of the few domestic manufacturers of SiC power discrete device products that have passed dual assessments.

Among them, APS 1200V automotive grade SiC MOSFET uses 18V/20V gate driving voltage, and 650V automotive grade SiC MOSFET uses 15V gate driving voltage.

Third is to jointly develop silicon carbide modules with customers to meet the needs of higher power and higher power density designs.

Fourthly, greater breakthroughs have been made in market development.

Due to the successful launch of the new generation of SiC MOSFETs and automotive grade SiC MOSFETs, we have established close partnerships with more leading enterprises in the fields of new energy, optical storage, charging piles, etc. in 2023. By jointly promoting the application of silicon carbide technology in various fields, we have solved technical difficulties, sharing resources and experience to accelerate product development and promotion, achieving mutual benefit.

The fifth is technological innovation.

As of 2023, we have continuously carried out technological innovation and product research and development in the field of silicon carbide, accumulating rich technology and experience. We have obtained over 40 independently developed patents, and are currently applying for more than 50 patents.

Hang Jia Shuo: Can you talk about your company's strategy and planning for silicon carbide in automotive specifications?

Chau Wing Chon: We have initially reached cooperation with leading enterprises in the field of new energy vehicles and successfully provided automotive grade silicon carbide MOSFET products to multiple customers for verification. At the same time, we are actively expanding cooperation with other automotive customers and striving to gain more market share.

However, in terms of business rhythm, we have not pursued fast entry into the market at APS because we believe that SiC power devices still face some challenges and bottlenecks that need to be futher overcome by domestic silicon carbide enterprises.

Firstly, the reliability of yield and design process should be ensured when using silicon carbide on vehicles.

The most critical factors in silicon carbide devices are the drift of threshold voltage (Vth) and gate oxygen reliability, which are the core parameters for evaluating the reliability level of silicon carbide MOSFETs. Domestic silicon carbide products still need to use reliability results to calculate how long it will take for the device to continuously meet the specification requirements.

Secondly, the product must pass the basic guarantee of AEC-Q101 to ensure that it meets the strict requirements of the automotive industry. APS focuses on quality management and reliability assurance. We strictly adhere to the quality management system of international standards and have passed ISO 9001 certification and IATF16949 audit. By establishing a reliable product supply chain and strict quality control processes, we can ensure product consistency and reliability, and provide stable product quality to customers.

In summary, we will continuously strive to overcome these challenges, improving the reliability and performance of our products, and making efforts to achieve the on-vehicle capability of domestically produced SiC chips.

5 Tactics to cope with industry competition

3 Major strategies to elevate leading position

Hang Jia Shuo: Cost is a double-edged sword. The large-scale development of the industry needs to be close to the low cost of silicon devices, but also to prevent being backfired by low prices. How do you view the low price and homogeneous competition in the industry? What are your company's good practices and suggestions?

Chau Wing Chon: The Chinese silicon carbide market is undergoing changes, and competition is becoming increasingly fierce. Enterprises are continuously reducing costs to compete for market share. In the face of the current market competition, we also believe that the industry cannot develop without competition. We will have 5 response measures in place.

On the one hand, we need to strengthen the coordination of domestic industrial chains and achieve price competitiveness. For this reason, we have chosen domestic and foreign substrate raw material suppliers to establish stable and close cooperative relationships in terms of epitaxy and substrate, ensuring the stable and efficient operation of the supply chain.

On the other hand, we need to enhance the reliability and delivery advantages of chips. For this reason, in terms of chip manufacturing, we cooperate with wafer foundry Jita Semiconductor. Jita Semiconductor is the earliest domestic foundry to mass produce 6-inch silicon carbide devices, and through their manufacturing capabilities and resources, we achieve product production and high-quality delivery.

Thirdly, we need to leverage our advantages in resources and experience. We also firmly believe that in the current market environment, we have our own core competitiveness. APS has been developing silicon carbide products since 2015 and has accumulated years of experience in this industry, gaining a stable customer base. In the past two years, the market has flourished, and our business model has also been recognized and supported by many downstream users. In the previous industry cycles, our product supply has always been completed with quality and quantity guaranteed, making us a reliable partner for downstream customers.

Fourthly, we need to increase investment in the new application market while maintaining our existing market share and stable growth. Especially in the fields of optical storage, new energy vehicles, and industrial automation, we will closely monitor market trends and customer needs, and strengthen technological research and innovation with our customers as our focus. By providing customized silicon carbide solutions, we will meet the needs of different industries and expand market share.

Fifthly, we will strengthen cooperation in the international market. The SiC device market is global, and various countries are actively promoting its development. We can learn from foreign experiences and technologies and establish partnerships with international enterprises, learning from each other and developing together. By conducting international cooperation, we can broaden market channels, improving the competitiveness and influence of our products.

Hang Jia Shuo: What plans and goals has your company set for 2024?

Chau Wing Chon: For APS, 2024 is a crucial year. We will further consolidate and expand our leading position in the silicon carbide market through three strategic directions, achieving sustained growth and comprehensive business development.

First, further expanding the application market of SiC MOSFETs.

Although our SiC MOSFETs have achieved significant growth in 2023, there is still great potential for development. Therefore, we will continue to work closely with partners to expand the application of SiC MOSFETs in new energy, optical storage, charging piles and other fields.

Second, we will focus on the automotive field.

In 2023, our SiC MOSFET obtained vehicle certification and launched application solutions such as 6.6kW OBC, 11kW OBC, and 2-3kW in vehicle DCDC. The related products have been commercialized and mass-produced, and will gradually be supplied in bulk.

In 2024, we plan to collaborate with more automotive manufacturers to further expand the application scope of SiC MOSFET, providing efficient and reliable solutions for key components such as power electronics and charging systems in electric vehicles.

Thirdly, continue to expand the "circle of friends" of SiC diodes.

We will focus on the application markets of industrial automation, power transmission, photovoltaics, and other high-power, high-voltage, and high current applications. We will work closely with customers to continuously improve product performance and quality, provide reliable products and technical support, and meet the needs of different industries for high-performance SiC diodes, providing the best solutions for customers' practical applications.